Chrome Anilox Roller

Chrome Anilox Roller

The chrome anilox roll is plated with copper layer on the surface of the roll core, and rolled to process the mesh, and then plated with hard chrome to increase its surface hardness and wear resistance. The inner wall of the mesh of the metal anilox roller is smooth, which is generally used in the printing ink transfer and high-precision coating industries, and the product has a high cost performance.

Main parameters

- Material:45# steel

- Surface Material: Chrome

- Surface Thickness: 0.06-0.08mm

- Surface hardness: HRC 62

- Screen line: 30~300LPI

- Max length: 4600mm

- Diameter: 50~600mm

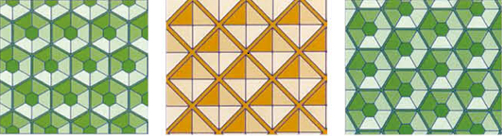

Common cell shape

tri-helical

diagonal truncated pyramid

diamond screen

hexagonal 60°

diagonal pointed pyramid

hexagonal 30°

Advantages

- Wear-resistant

- higher hardness

Cost-effective

Quality Precision

- Cylinder runout : 0.015-0.03mm

- Cylindricity : 0.01~0.02mm

- Balance quality lecel: G2.5

CONTACT US

Connect

Phone: 86-21-60674601

Mobile: 0086 13918369684

Whatsapp:0086 13918369684

Fax: 86-21-60674601

Email: Abel@herzpack.com